The technical indicators of a high-low temperature test chamber have a systematic and multi-dimensional impact on experimental results. The core lies in whether it can accurately simulate the target environmental conditions and maintain controllability throughout the experimental process. The following is a detailed analysis of its impact mechanisms and practical cases from several key indicators:

I. Adaptability of Temperature Range and Extreme Values

The temperature range determines whether the test chamber can cover the extreme temperature conditions in which the tested samples are actually used. For example:

Insufficient Temperature Range: If the highest temperature of the equipment is 150°C, but the product needs to be tested at 200°C (such as aerospace components), it will not meet the experimental requirements, leading to invalid test results.

Temperature Gradient Design: The national standard GB 10592 stipulates a deviation of ≤±2°C. If the actual deviation of the equipment exceeds the standard, it will cause the experimental conditions to be inconsistent with the design parameters. For example, in the performance test of electronic components at -65°C, if the actual temperature only reaches -60°C, it may conceal their failure risks under extreme low temperatures.

Case: In the charge-discharge testing of automotive batteries within the range of -40°C to +85°C, if the equipment’s lower limit of low temperature is only -30°C, the low-temperature performance data of the battery will not truly reflect its performance in actual cold regions.

II. Impact of Temperature Uniformity and Spatial Consistency

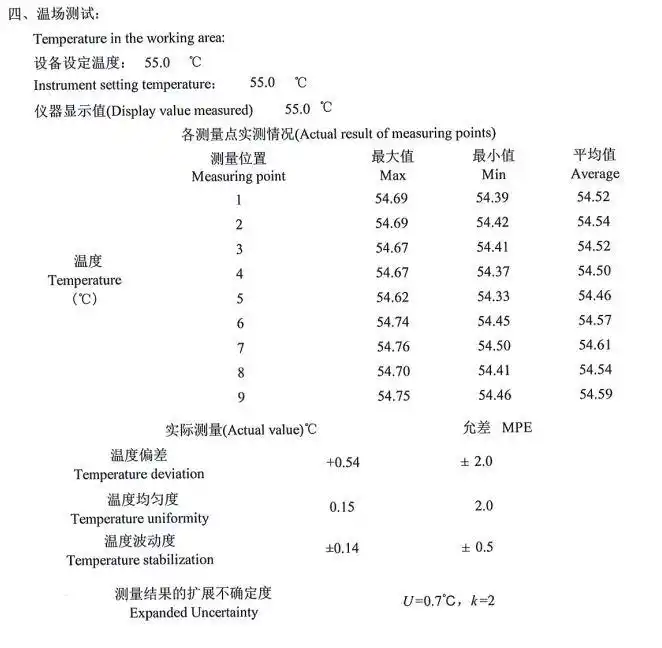

Temperature uniformity (usually required to be ≤2°C) directly affects the spatial consistency of experimental conditions:

Consequences of Insufficient Uniformity: In the thermal stress test of electronic components, if the temperature difference between different positions in the box exceeds ±2°C, some components may age faster due to local high temperatures, while components in other areas do not reach the test threshold, leading to distorted overall life assessment.

Definition of Working Area: According to the standard, the working area needs to deduct 10% of the space from the box wall. If the samples are placed beyond this range, they may be affected by greater temperature fluctuations in the area close to the box wall, resulting in abnormal data.

Case: In the test of an LED lamp in a test chamber with non-compliant uniformity, the edge area of the lamp did not trigger the heat dissipation design defect due to the lower temperature, while the center area overheated, leading to a misjudgment of “qualified”.

III. Temperature Fluctuation and Time Stability

Temperature fluctuation (such as ±0.5°C) reflects the short-term stability of the equipment in maintaining the set temperature:

Excessive Fluctuation: In material fatigue testing, frequent temperature fluctuations (such as ±2°C) may introduce additional thermal stress, accelerating the expansion of material cracks and causing the experimental results to deviate from the slow temperature change patterns in actual use scenarios.

Relevance of Control System: A temperature control system using PID algorithm (as described) can effectively reduce fluctuations, while low-end equipment may cause biological samples (such as vaccines) to become inactive in preservation tests due to repeated temperature exceedances beyond the critical value.

IV. Dynamic Simulation Capability of Temperature Rise and Fall Rates

The temperature rise and fall rates (such as 1-3°C/min) determine whether the experiment can simulate the temperature changes in real environments:

Risks of Too Fast Rates: High molecular materials may develop micro-cracks due to uneven internal stress during rapid cooling, while slow cooling in actual use may not cause such problems, leading to overly stringent test conclusions.

Matching with Standards: Some industry standards (such as IEC 60068) explicitly require temperature rise and fall rates to be ≤1°C/min. If the actual rate of the equipment is too fast, the test results will not pass certification.

Case: A certain automotive sensor cracked in its packaging at a cooling rate of 5°C/min, but the actual cooling rate during vehicle cold start was only 0.5°C/min, showing a disconnection between the experimental conditions and real scenarios.

V. Humidity Control Precision and Composite Environmental Effects

Humidity control precision (such as ±2%RH) is particularly critical in humid and hot tests:

Impact of Insufficient Precision: In the moisture-proof test of PCB boards, if the actual humidity value is 85%RH while the set value is 80%RH, it may lead to an accelerated moisture absorption rate, resulting in a misjudgment of “moisture-proof coating failure”.

Synergy of Sensors and Algorithms: High-precision humidity sensors (such as capacitive ones) combined with PID control can reduce the risk of fogging on precision optical devices (such as lenses) caused by humidity fluctuations.

Case: A certain military communication equipment was tested in a test chamber with a humidity deviation of ±5%RH and showed “humidity resistance qualified”, but in the real tropical environment, it short-circuited due to local high humidity.

VI. Synergistic Effects of Other Indicators

Airflow Speed: Excessive wind speed (such as >1.7m/s) may accelerate the heat dissipation of the sample surface, making the internal temperature gradient inconsistent with the real static air environment, affecting the verification results of heat dissipation design.

Chamber Size: A small space may lead to sample stacking, obstructing air circulation and artificially increasing temperature non-uniformity.

Refrigeration System Performance: The application of cascade refrigeration and environmentally friendly refrigerants (such as R404A) ensures low-temperature stability below -70°C, avoiding experimental interruptions due to refrigerant leakage or reduced efficiency.

VII. Equipment Safety and Experimental Continuity

Safety protection devices (such as over-temperature protection and leakage protection) do not directly affect the data, but equipment failures may lead to experimental interruptions. For example, compressor overload shutdown may cause the loss of long-term reliability test data.

The indicators of high-low temperature test chambers affect experimental results through three dimensions: environmental simulation accuracy, dynamic response capability, and spatial consistency. When selecting equipment, it is necessary to comprehensively consider test standards (such as GB 10592), sample characteristics, and actual application scenarios, and ensure that the indicators remain up to standard through calibration and maintenance. For example, in electronic component testing, priority should be given to temperature uniformity (within ±0.3°C) and controllability of temperature rise and fall rates, while in material aging testing, it is necessary to ensure humidity control precision and long-term operational stability. Only when the equipment indicators are highly matched with the experimental requirements can real and reliable data be obtained to support product optimization and certification.